Introduction

Loss-in-Weight Feeders

DPH Engineering have seventy years of experience, offers the broadest range of loss in weight feeder systems of any manufacturer. Each of its high-performing feeders provides precision-class accuracy and repeatability in demanding and strenuous process environments. We offer integrated material agitation zones, specialized auger designs and a wide range of proprietary feed algorithms to ensure reliable feeding of difficult materials. When paired with one of Thayer Scale’s rugged, counterbalanced platform or cable scales, the combination is a robust gravimetric feeding solution that integrates seamlessly into existing plant processes.

DPH engineering loss-in-weight feeders incorporate a volumetric feeding subsystem designed to provide consistent, reliable metering of the target material at desired flow rates. (Flow rates may be as low as two grams/minute and as high as 100,000 pounds/hour.) To this volumetric feeder, we pair a fully mass-counterbalanced platform or cable scale designed to provide maximum signal and ensure accurate, reliable weight measurement in the most difficult operating conditions. We offer a powerful set of proprietary add-on accessories designed to solve problematic flow issues, such as bridging, flushing, adhesion, and cohesion. In addition, our instrumentation has powerful software routines specifically aimed at optimizing a feeder’s performance, such as output compensation, disturbance control, linearization, density compensation during refill, temperature compensation, and automated calibrations.

Our loss-in weight feeders provide:

Extended operating range

Durable scales that withstand abuse

A single load cell that can be accessed and/or replaced without removing the feeder/weigh hopper

Flexible mounting options: floor-mounted, rotating, stationary, wheeled, forklift-based, suspended

Fast access for cleaning

Screw augers that can be changed without tools

Damage-free handling of delicate and/or fragile materials

Benefits of Mass Counterbalanced Weighing

Mass counterbalancing provides the means to maximize the differential weight signals representing flow rate which permit operation over higher turn down ratios and enables longer times between hopper refills. The reduction in noise relative to signal levels also permits operation using higher controller gain settings. This is particularly beneficial when the feeder is set to follow a variable demand (set-point) signal. Also, calibration confirmation using test weights of a scale with mass counterbalancing is simpler and quicker owing to its leveraging advantage.

Built to Survive

The question of “robustness” is also a major factor that must be considered given the harsh environments loss-in-weight feeders operate in. Feeders that rely on gross weight measurements are supplied with vessels and feeding equipment that are light in weight for obvious reasons. Thus the gauge of steel used in hoppers and feeders, the size of shafts, bearings and motor drives elements etc. are usually marginally sized to meet an acceptable repair/replacement time span as opposed to a more desirable 10-year life span. This is why we recommend that all of our clients request that the weights of these various dead-load components be specified in the quotation. We’re happy to do the same!

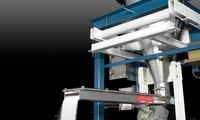

Loss in Weight Feeder System

Vibratory Feeders

Screw Feeders